Explore Fernweh

Designers & Architects

Resources

Part of

The Fjoon CollectionStarting at

$ 2,650.00

The Fjoon (pr. fyoon) collection rose out of a multi-year obsession with high end upholstery as well as an infatuation with wood joinery and principles of chair strength from the broader chair making community, especially windsor chair makers. My musings led me to include what are now a few of my favorite aspects of fjoon.

The fjoon occasional/dining chair features a vacuum-laminated upholstered seat with a sweeping compound curve, stepped mortise-and-tenon joinery with a friction wedge, and a patented wood plug system which allows for re-upholstery down the line without having to destroy / re-fabricate any chair parts. We meticulously selected ten offerings of upholstery leathers and textiles of the highest quality from our newest partners Sorensøn and Kvadrat.

White Ash Wood Care: For our White Ash products, we have transitioned from our previous white finish to a traditional Danish soap finish. Since hardwood is a natural material there can be subtle variations in color and grain. To see an accurate representation of our finishes, swipe to see the photo of our white ash soap finish in our swatches.

For smaller items (Tripod Table, Oxbend Chair, and Oxbend Stool) we are usually able to parcel ship, via UPS. You’ll be able to track them via your order confirmation, and standard transit time is 3-5 business days. For larger items (everything not listed above) our standard shipping is via private van delivery. We cultivate a network of independant white glove shippers who ensure the best care while transporting our pieces of furniture to your home. If you need additional services, please contact us.

Because Fernweh Woodworking offers furniture on a made-to-order basis, we do not accept returns. The Warranty Period for furniture purchased from Fernweh Woodworking is 5 years from the date of purchase. During the Warranty Period, Fernweh Woodworking will repair or replace, at no charge, products or parts of a product that proves defective because of improper material or workmanship, under normal use and maintenance.Read more about our Limited Warranty here.

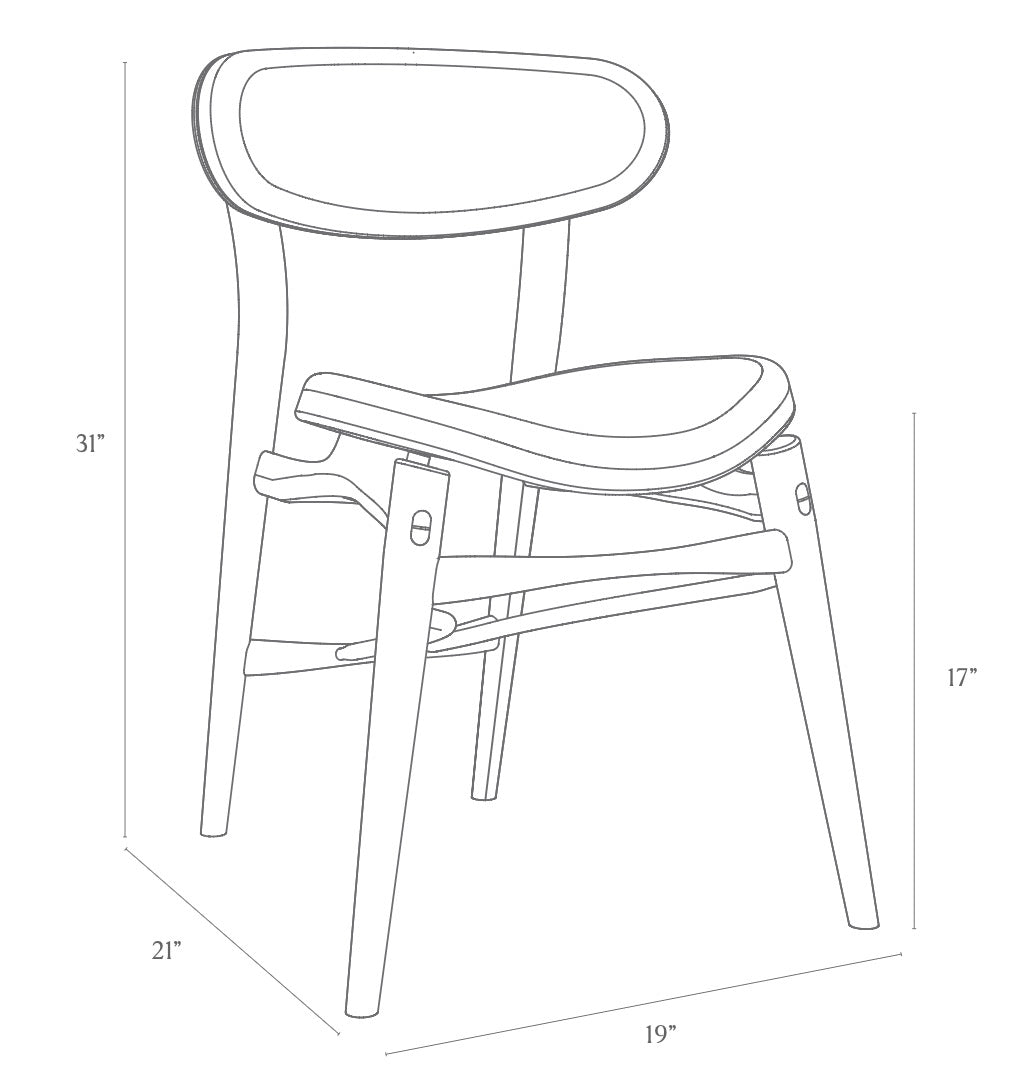

Total Dimensions: 21” total depth, 17.5” seat depth x 19” wide x 31” tall

Terms: All pieces made to order. Inquire for current lead time. Made from domestic hardwoods with VOC-free finish.

In Partnership with Kvadrat

We love accommodating COM/COL for our trade clients - required yardage for one chair is 12 square feet.

In Partnership with Sorensen Leather

The Fjoon (pr. fyoon) collection rose out of a multi-year obsession with high end upholstery as well as an infatuation with wood joinery and principles of chair strength from the broader chair-making community, especially windsor chair makers. My musings led me to include what are now a few of my favorite aspects of fjoon

This is our first upholstered piece, and I was determined to develop ways to make the surface of the seat feel comfortable while looking elegant. Each seat is quite sturdy, formed on a vacuum press in our shop and consisting of 6 layers of material, being further strengthened by the shape of the compound curve. After this process, we add foam and upholstery. The undersides are also upholstered, and they clam-shell into the upper section seamlessly. There is a pocket stitched on to the bottom of each seat containing a key for any future re-upholstery disassembly… see more below.

As I dreamed about what would define this chair, I knew I needed to develop an exceptionally strong joint in order to keep the parts small and minimal while also being sturdy. The answer to this was a stepped mortise and tenon, which can be found where each seat support connects to the front and back legs. The stepped nature of the tenon adds mechanical strength while maintaining a seamless connection; wedging the smaller tenon makes for an incredible friction fit, while keeping the larger tenon from splitting.

This system was developed by myself and Alex Collins, a principle architect at Blue Forty, and we were so excited by the results of our explorations that we filed a patent on our final design. Six custom wood plugs are affixed securely in place, hiding the structural hardware connecting the wood parts to the upholstery frames, but they are also removable via a custom aluminum key located in a small pocket on the underside of the seat. This allows for disassembly of the furniture on the off chance that the upholstery gets damaged or needs to be replaced.

In our extensive material selections process, we chose five upholstery leathers from Sørensen Leather, and I visited their facility in Denmark before the launch, getting to know their company and materials processes even better. Secondly, we selected five stunning wool textiles from Kvadrat textiles, which complement our three standard wood options beautifully.”

Our woodworking team appreciates that each chair includes all three standard methods of creating curved wooden parts - steam bending, bent lamination, and shaping. Which brings me to one of my other favorite aspects of fjoon - it really was a team design effort at Fernweh Woodworking to create this collection. Each member of the team gave critical feedback, did countless sit tests, built key fixtures, jigs, and prototypes, as well as aiding in our final materials selection for our ten new upholstery options.